Search results for: 'bun ph 01 press hall business starter'

Compare Products

You can select up to 6 products to compare.

You have no items to compare.

-

TRANSPRO HEAT PRESS AND ROMEO STARTER PACKAGE Item #: BUN-086As low as $1,199.00 Regular Price $1,296.00

-

CUSTOM TRANSFER AND HEAT PRESS BUSINESS PACKAGE Item #: BUN-111As low as $1,269.00 Regular Price $1,499.00

-

SUPACOLOR HEADWEAR AND CAP PRESS STARTER PACKAGE Item #: BUN-109As low as $459.00 Regular Price $569.00

-

TRANSPRO HEAT PRESS AND JULIET CUTTER STARTER PACKAGE Item #: BUN-068As low as $905.00 Regular Price $1,155.00

-

-

-

-

Mom Bun Flowers Cut File Item #: CF101281Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Wispy Willow Designs$3.49

-

-

-

USA Kid Bun Cut File Item #: CF103149Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Digital Diva$2.00

-

Messy Bun Bandana Cut File Item #: CF101276Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Wispy Willow Designs$3.49

-

Pink Plaid Curly Messy Bun Cut File Item #: CF103055Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Digital Diva$2.00

-

SUBLIMATION AND DRINKWARE BUSINESS PACKAGE Item #: BUN-071As low as $1,549.00 Regular Price $1,787.00

-

-

USA Mom Bun Cut File Item #: CF103150Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Digital Diva$2.00

-

-

-

Messy Bun and Getting Stuff Done Cut File Item #: CF102964Format: SVG, PNG, DXFArtist: Sugar Sugar$3.00

-

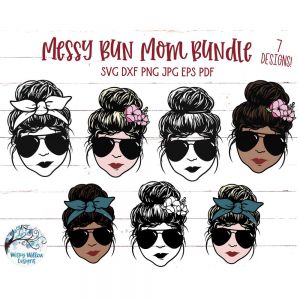

Messy Bun Mom Bundle Cut File Item #: CF101277Format: SVG, PNG, EPS, DXF, PDF, JPGArtist: Wispy Willow Designs$4.99